Part 1 is here -> Building a Frankenstein Amiga: A Journey of Restoration and Customisation

Welcome to the final part of my Amiga 500 Frankenstein build, which I’m doing for the More Fun Making It charity auction. This journey began with a couple of neglected and yellowed A500 cases. Well, to be precise, it involved parts from at least three different cases that had all seen better days. One of the bottom halves was particularly damaged, so I swapped it out for a better one. When this project is finished, it’s going to be more of a Cinderella transformation rather than an ugly sister. However, I must warn you, the final color might be a bit of a Marmite situation – you’ll either love it or hate it.

First things first, I had to remove all the badges from the case and give it a thorough clean. This thing needed to be absolutely pristine before I could change the color.

With the case cleaned, the first phase of the color transformation involved spraying it with a black undercoat. This black layer acts as a plastic primer and base coat for the wild color that’s coming next. I must admit, it did look pretty good in black, but black Amigas are quite common these days. We’re going for something a bit more unique here. I planned on adding another two, maybe three, coats of the crazy color, followed by some lacquer to ensure the finish is robust enough to withstand regular use.

After about two weeks of painting and letting it dry, I decided to take the case with me to RMC the Cave to get Lee’s opinion. Here’s a picture of me at the RMC Retro shop.

With the paint now well and truly dry, I could finally put the finishing touches on the case and place the Amiga 500 board in its new home. The next stop was kickstart, where Reese showed his skills by playing any Doom game on any platform, even if it’s not an Atari. I spent much of the day chatting with people and hanging out with other YouTubers in the community room.

At the end of the day, we had a small signing ceremony, which was a great way to wrap things up. Here’s a quick look at that moment.

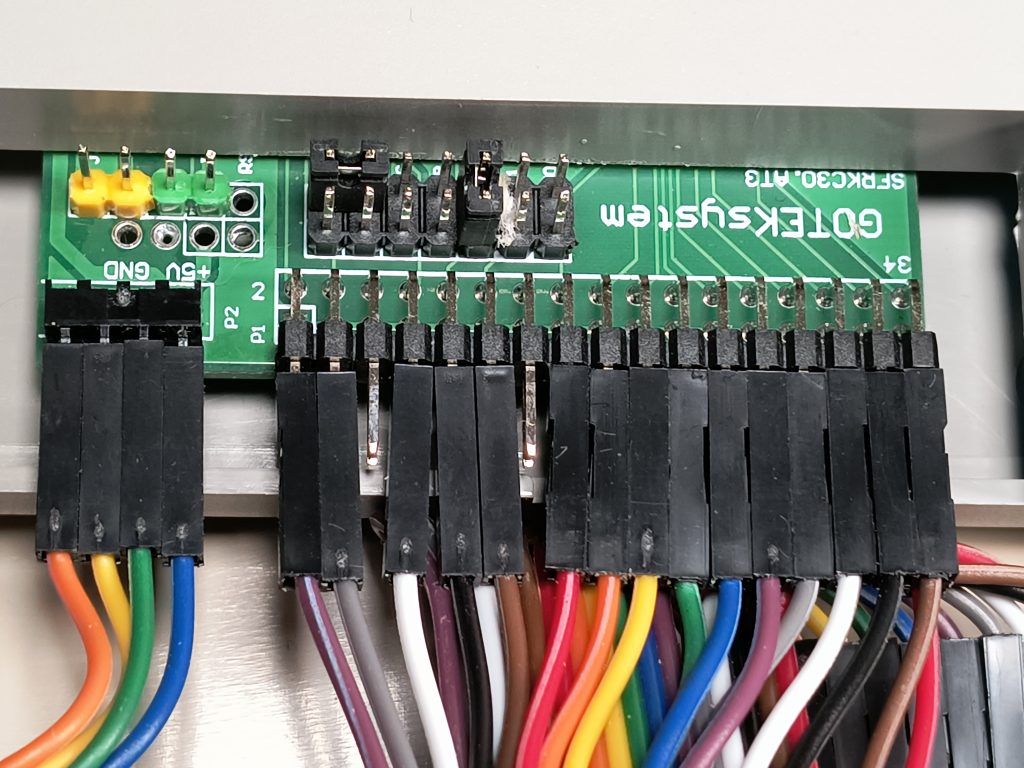

You might think that’s the end of the journey, but when I got back a couple of weeks later, I needed some footage for the end of this video. When I tried to fire up the Amiga, it was dead. So, I immediately began troubleshooting. After pushing some chips and trying again with no luck, I knew it was time for the big guns. I started by eliminating the CPU and Gary, the usual culprits for a black screen on an Amiga 500. I then beeped out the entire CPU socket and found one pin that wasn’t connected correctly. Turning the board over, I checked the trace and found continuity. Confused, I turned the board back over and lost continuity.

Thinking I was just too tired, I called it a night. Day two brought no change. Looking at the underside of the board with magnification, I saw that the trace was slightly damaged. The flexing of the board when turning it upside down was enough to make contact. So, I put a piece of wire across the damaged trace, and it was solid again. The Amiga fired up like nothing ever happened.

With the board now fully functional, I tidied it up and added any finishing touches I thought necessary. Then, I buttoned it up, put it back in the box, and finished the video. This time, I made sure to test it both before and after putting the lid on.

I’ll be doing something else in a similar style for another charity auction soon, so why not subscribe to my YouTube channel and make sure you don’t miss that video when it comes out? It’s free and helps the channel.

Thanks for following along on this journey!

Cheers!